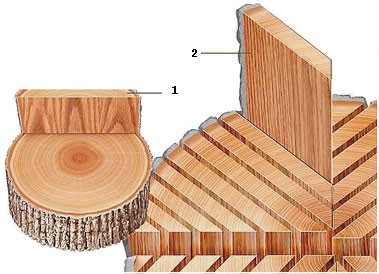

Radial cut

Radial cut is the way of sawn cutting where the cut passes through the core barrel. Density of such boards is homogeneous in color and texture; the gaps between the rings are minimal. Cutting boards – 2 are resistant to outside influence, practically not subjected to deformation and have high degree resistance to wear.

Cutting boards with radial cut has shrinkage ratio of 0.19% and its coefficient for expansion is 0.2%.These indicators for cutting timber are two times better than for board with tangential cut.

Cutting boards with radial cut has shrinkage ratio of 0.19% and its coefficient for expansion is 0.2%.These indicators for cutting timber are two times better than for board with tangential cut.

For board with radial cut shrinkage and inflator process goes by the fiber width- board thickness and for tangential cut it goes by board width because the fibers here are placed in width. There is practically no crack in baseboard, parquet board, timber imitation, block house and lime with radial cut which is not the case in such products with tangential cut.

For board with radial cut shrinkage and inflator process goes by the fiber width- board thickness and for tangential cut it goes by board width because the fibers here are placed in width. There is practically no crack in baseboard, parquet board, timber imitation, block house and lime with radial cut which is not the case in such products with tangential cut.

Price for boards with radial cut is quit high because the output of radial cutting board is 10 - 15% of the total.

The scheme of sawing for maximum quantity of boards with radial cut - 2 and half cut - 3.

Tangential cut - is the way of sawn cutting where cut surface passes within the core of the ring touching the tree layer. Such boards have bright texture and nice wave drawing. Tangential cut boards – 1 have a higher percentage of shrinkage and expansion (Inflator) but the price is affordable.

Tangential cut - is the way of sawn cutting where cut surface passes within the core of the ring touching the tree layer. Such boards have bright texture and nice wave drawing. Tangential cut boards – 1 have a higher percentage of shrinkage and expansion (Inflator) but the price is affordable.

Radial cut - 2 is the way of cutting logs where all fibers in board go along the annual rings. In radial cut cutting timber has the best physical and mechanical property. Firmness and hardness of cutting timber is bigger than the same in tangential cut.

The total volume obtained from radial cut-

Choosing among the optimization criteria of obtaining the maximum finished boards from total volume of radial and half radial – 3 cut, technologist determines the percentage radial board.

Choosing among the optimization criteria of obtaining the maximum finished boards from total volume of radial and half radial – 3 cut, technologist determines the percentage radial board.

Radial cutting - 2 can be carried out on other machines, but the percentage of radial board output on other machines depends on how operator has cut log.

Usually this figure is much lower than 50%. Due to the microprocessor control system and optimization system for UP-

Summary: radial cutting timber has the best physical and mechanical properties. On the longitudinal sawing machines UP-700 exit wood cutting board method - radial cut is up to 60%.