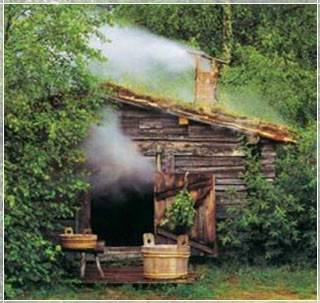

Russian steam bath

The effect of Russian steam bath and its medical qualities are known to everyone. At the current pace of life it is necessary to make a break and breathe the air. What else than own steam bath can provide such possibility.

The effect of Russian steam bath and its medical qualities are known to everyone. At the current pace of life it is necessary to make a break and breathe the air. What else than own steam bath can provide such possibility.

Since ancient times in Russia the most popular building material for such construction was timber. It has always been and remains a quality base for providing heat and dryness of the room. In wooden steam bath the loss of heat is minimal because even without heating the room is cooling very slowly.

Steam bath made of logs is long-lasting, and the construction from solid timber is environmentally clean and hygienic. Logs used in construction of steam bath have smaller external processing than timber and hence their risk of infection with fungus and rot is minimal.

Best wood for the construction of steam bath is conifer tree; especially cedar but Siberian larch is also good. General principles for steam construction bath are simple. First the wall is building from logs which are mounted to one another cross at the corners. Pre-stored logs should be used. Such logs are dried according to specific technology and should be cleaned from bark. It is best to choose carefully processed round logs with a diameter from 22 to 26 cm (recommended diameter depends on the area of construction - what it north, the log has to be thicker). Logs are selected to match the diameter and assembled in opposite sides in height and composing with cap in length. The obligatory requirement is the spaces (gaps) between logs that occur as a result of shrinkage of the walls near the door area. Openings may be filled by any thermal material or ordinary tow. Bottom row based on the foundation, should be of Siberian larch.

Best wood for the construction of steam bath is conifer tree; especially cedar but Siberian larch is also good. General principles for steam construction bath are simple. First the wall is building from logs which are mounted to one another cross at the corners. Pre-stored logs should be used. Such logs are dried according to specific technology and should be cleaned from bark. It is best to choose carefully processed round logs with a diameter from 22 to 26 cm (recommended diameter depends on the area of construction - what it north, the log has to be thicker). Logs are selected to match the diameter and assembled in opposite sides in height and composing with cap in length. The obligatory requirement is the spaces (gaps) between logs that occur as a result of shrinkage of the walls near the door area. Openings may be filled by any thermal material or ordinary tow. Bottom row based on the foundation, should be of Siberian larch.

Because of strong wood shrinkage and its pressure on the insulation material at the seams, the walls of a steam bath will shrink to 5% of wall height in the next two to three years. When the precipitation process is finished, the seams between logs should be isolated once again and front side walls and corners are processed with boards.

Raising the walls from logs requires much more time than the same but with using timber. The roof of steam bath made from logs consists of ridge timber and rafters as well as support (console) and sheathing, which subsequently falls and fireproof roof (primarily asbestos cement). Roof pitch is calculated taking into account the potential load of snow.

It is recommended for the floors in steam bath made from logs to choose shaving board. Such base boards are silent and resilient. Boards are planked heart up on the joists, laid every half-meter from each other. It is only 5 or 6 board is nailed and the final nailing made only year later (after shrinkage). Each floor element, as well as walls should be disinfected.

It is recommended for the floors in steam bath made from logs to choose shaving board. Such base boards are silent and resilient. Boards are planked heart up on the joists, laid every half-meter from each other. It is only 5 or 6 board is nailed and the final nailing made only year later (after shrinkage). Each floor element, as well as walls should be disinfected.

If you want to built steam bath from logs the best solution is to turn to professionals. Nowadays there are enough experts for such unique buildings works.